Tackling the Maintenance Fixed Cost Challenge Through Cost Effective Maintenance

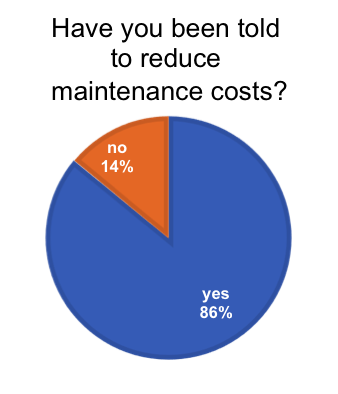

In the past few months I have been privileged to have worked with maintenance professionals in Africa, Asia, Europe, America and the Middle East including people from a wide range of backgrounds from oil refineries to mines and on to hotels. As I have done this, I have asked them similar questions around how they manage costs and have found a remarkable level of consistency, no matter the region or the sector. At the heart of the issue of having their budgets reduced. Here are the key questions and the answers I got:

So, this is pretty much an international experience. Whilst there were a few companies where maintenance costs were not challenged, this is relatively rare wherever you work.

There is a simple truth, fixed cost challenge is something almost everyone is going to have to face and it is unlikely to go away.

This is a reality we have to learn to manage.

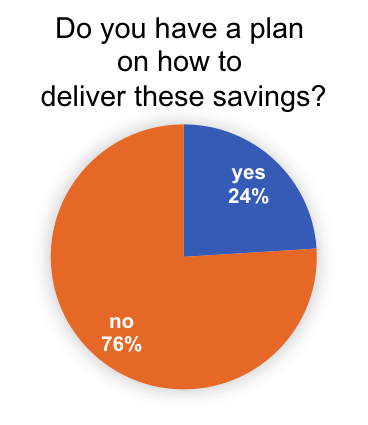

So, with this in mind, we wanted to understand how people are managing this challenge.

In truth, the answer is that most people are not. Simply looking to spot cost saving opportunities as they arrive is not enough. Neither is telling people to avoid spending money unless they absolutely have to. Both often drive the wrong behaviours.

None the less, some engineers have looked for solutions. They have looked for waste and opportunities to take costs out in a structured way.

Unfortunately, there is not much effective support in this area – look for a book on Reliability or Maintenance Management on Amazon and you will get 20 times as many hits as when you search for cost reduction.

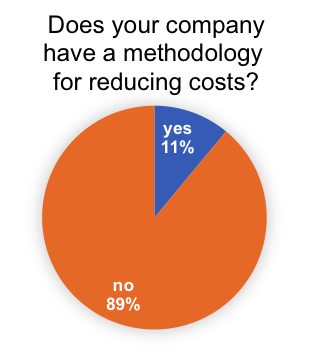

This is a major gap. Almost everyone felt they were asked to reduce costs but not given any help. Many felt that many of their costs were driven by other departments who have no interest in helping them reduce costs. In fact many felt that other departments had targets that demanded more maintenance!

It’s hardly surprising that many people feel hard done by! Where companies did “help” many complained that this was in the form of travel bans, complicated approval processes, cutting budgets “to provide focus” and reducing the spend on training.

Very few people could describe a coherent and structured methodology for reducing costs without undermining performance. It is unfortunate that there is no recognised methodology for one of the most common maintenance challenges. Most people are trained in reliability improvement, planning or auditing skills but not cost reduction.

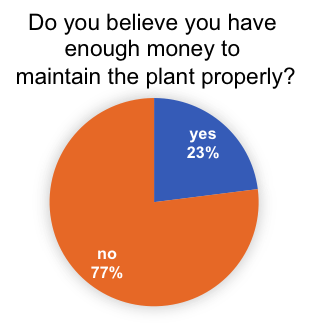

This brings us to the next and quite concerning question. Over three quarters of the people we spoke to felt that they did not have enough money to maintain the plant properly. This is alarming with many people giving examples of reliability and performance losses that dwarfed the cost cutting that caused them.

We are beginning to see evidence that the majority of cost reduction projects fail (60-70%) in the long-term and end up costing more than they save. This all hints to the need for a more effective methodology.

But, let’s not forget that some people succeed so there is a way.

One final question…..

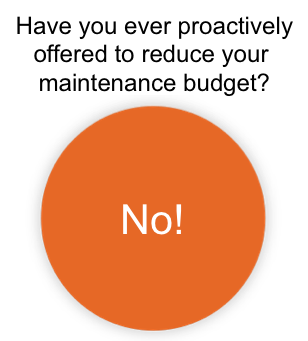

Whilst we have met maintenance professionals who have offered to reduce their own budget, none of the people we spoke to in this sample (63 people) had done this. In fact, most thought this was as crazy idea!

People generally felt that one of their most important roles was to protect the maintenance budget.

This was a relatively small sample group, but we’d consider the spread of answers to be reasonably representative of the discussions we have had less formally over the years with the hundreds of maintenance professionals we have worked with on consulting assignments or trained on our maintenance courses. So, in summary, the overwhelming opinion from maintenance is:

“Fixed cost challenge is not going away”

“Fixed cost reductions are generally inflicted on maintenance rather than discussed”

“This is difficult to do so requires a systematic approach”

“Very few people have an appropriate methodology to tackle this”

“Most cost reduction programmes fail rather than improve”

“You need to fight to get the money you need”

I have worked in or with maintenance teams all of my career, so I really understand this position. However, I have also worked with other departments including finance and general managers and I’ve come to learn another side to this story. Some of the things other departments have said to me have been very difficult to listen to:

“This is a competitive world and we cannot duck the fixed cost challenge”

“Most maintenance teams waste money

By doing work that is not necessary

By not planning work efficiently

Because tool time from the technicians is often low but rarely challenged”

“We don’t believe them when they say it is not possible to reduce costs!”

“Maintenance departments rarely offer cost reductions, which is frustrating, so we inflict them on them!”

The first time I heard these comments I thought it was unfair and felt defensive, but now I understand their perspective. I generally find that maintenance people (my brothers in arms) get very angry when people suggest they are not doing all they can to reduce costs. Unfortunately, maintenance costs cause a lot of tension and arguments all around the world - I suspect some people reading this paper are already feeling their temperature rise!

Whoever you agree with, it is clear that we need a solution.

One final comment. As a general rule most maintenance staff do not know the commercial side of the companies they work for - they don’t know how profit is generated and don’t see this as their job. Many of the senior managers simply said this is not important for maintenance. This is a big problem, I’ll come to this later.

Here are some of the key steps we recommend people to take.

1. Define the business strategy and share this with maintenance

The goal of any business is to make profit. We might do this through different ways, but ultimately all businesses need to make a profit to exist. Of course, this has to be done safely and ethically, but all companies were founded to make profit and usually to make long term profits. As a consequence, everyone in the company needs to understand their role in this.

In the case of maintenance, this is essential. We need to move the focus away from just cost and on to profit. All maintenance should be seen as an investment with the cost weighed against its contribution to the business goals. Some maintenance will have a big contribution to reliability, product quality or long-term performance so may be worth spending more on since the returns are high and some maintenance will clearly be less valuable, so can be reduced or even eliminated. However, if you cannot weigh up the value of work, you end up distributing effort evenly or against other measure that may not be so important to the business.

2. Take the initiative and make this a positive process

Why is this important? Because so long as you wait for someone else to inflict cost reduction demands on you, you will always feel and behave like a victim. By taking the initiative you now own the process, you can change the view others have of maintenance and you can set your own programme.

Another thing to consider is that the things you need to do to reduce costs (better planning, clearer focus, less distractions and better teamwork) are things most people will sign up to happily. This is not just about reducing costs, it is about doing things well and improving profit.

3. Do less work!!!

I’ve mentioned earlier that focusing on profit and viewing maintenance as an investment will lead to cancelling some work because they are bad investments. However, there is more to go after.

Even if a job is clearly making a big contribution to profitability or safety goals, there may be parts of the scope that are less important than others, some that people are doing because it’s interesting or because “we’ve always done it this way.” Sometimes we use equipment policies, methods and tooling that force us to do more work than ideal and sometimes we do jobs too often.

Every single part of a job should be challenged with the simple questions:

-

What is the purpose of the overall task?

Will this part of the job contribute to this?

- Do we need to do all of it?

- Do we need to do it this often?

The great thing about removing work is that it permanently reduces bad maintenance investment and also risk – you can’t get hurt, cause a quality problem or extra costs if you are not doing the work at all!

4. Use better planning to do work smarter

Most people accept this but not everyone does it effectively. Good planning should provide a clear method that will be both effective and efficient. It should also include a continuous improvement loop (very few people do this effectively) that asks:

-

Was the method effective and did the job run smoothly?

- What could be done better next time?

- What do we know about the failure mode, what is causing it and rate of degradation?

- Can we change the maintenance policy to deal with this better?

- Can operations do something to reduce the problem?

- Do we need to do this less often or more often?

5. Get closer to the front line and do everything you can to make it easier for people to do their jobs.

Lots of people use the term “Our greatest asset is our people” but they seem to forget that this includes the maintenance and production technicians. Too many people have lost touch with the shop floor.

Many people do not measure wrench/tool time or are measuring it wrong. Most of the people we study are shocked by how low their tool time is and many blame the supervisors and technicians. This is not fair since we normally find the root causes of low tool time are poor planning, bad systems and work processes or ineffective support from other departments.

I love the shop floor. This is where you see just how well all of the company systems, planning and other department come together. You cannot do this remotely, you have to make visits, ask what helps and hinders people trying to get work done on the asset. Only by doing this will you understand the issues, the causes and have any chance of fixing these. It’s a wonderful way of getting to the bottom of what is going on and also of engaging the technicians – they are rarely short of ideas!

6. Encourage entrepreneurial thinking and free up clever investment

Once people start focusing on profit they begin to change their decisions and think more innovative. It is exciting to consider yourself an entrepreneur, contributing to increasing profits with different ways of doing things. These do not have to be high tech solutions with simple ideas such as improved tooling or applying formula 1 pit stop style team working.

7. Improve relationships with suppliers for reduce their costs to you

Most people share the cost reduction burden with their suppliers by demanding discounts! This can do a lot of damage since suppliers can resent this and will move to different customers if they can. If they can’t they may reduce quality which could harm your business.

Pace setters have good relationships with their suppliers and contractors and look for a win:win scenario where they can work together to improve efficiencies, make it worth suppliers investing in the contract and share the benefits.

Related Blogs

7 Steps to Reduce Maintenance Fixed Costs

Very few maintenance staff can describe a coherent and structured methodology for reducing maintenance fixed costs without undermining performance. It is unfortunate that there is no recognised methodology fo...

What are you planning for? Surviving or thriving?

We have done a lot of maintenance reviews over the years and one of the key areas we check is how maintenance work is planned and managed. Most people recogn...

The value of good planning and scheduling

A genuine step change in performance If ever you want is a case study on the value you can gain from effective planning and scheduling this is it. I have just completed a proj...

Cost Effective Maintenance

Achieving High Performance at the Lowest Possible Cost One thing that is common wherever I visit, no matter what the region or the sector, is the strength of opinions on the cost of maintenance. ...