The value of good planning and scheduling

A genuine step change in performance

If ever you want is a case study on the value you can gain from effective planning and scheduling this is it. I have just completed a project with a client who achieved some of the best results I have ever seen. In their own words they have converted a multi-million-dollar maintenance programme from a project most expected to fail to one that has now gone well beyond the standards most people thought possible.

The start point

Our client was facing an extremely challenging programme of work that included technical, safety and logistical challenges on a level that they had historically struggled with. To be fair, this was an offshore facility and benchmarking showed that this type of programme has caused problems across the world - even for the leading operators. To add to the challenge, the consequences of failing to meet the deadlines would be significant for the business.

The Process

Our client implemented our optimisation process and at the heart of this are the principles of challenge planning. This process allowed them to go beyond the traditional planning process, to innovate in the methods used, optimise the way people worked and take a different approach to the way work was scheduled.

Initially people simply did not believe it would be possible to meet the programme. It’s not that they were poor performers; they had worked hard at this type of work in the past and achieved competent results, but the new programme would mean beating their best ever performance by a considerable difference. However, once the challenge process began to generate new ways of working, people started to become optimistic. They began to believe that the targets were achievable and contributed more ideas to improve. Together they identified a few “game changing” options, but also a much bigger collection of small changes.

One of the most important changes they made was to look for best practice outside their own sector. They took their targets from historic benchmarks from offshore but looked for best practice and planning tools from anywhere they could. They used the principles of formula one pit stops, tools from the automotive industry and ideas from the chemicals sector. All were brought together in the challenge planning and optimisation process.

What they achieved

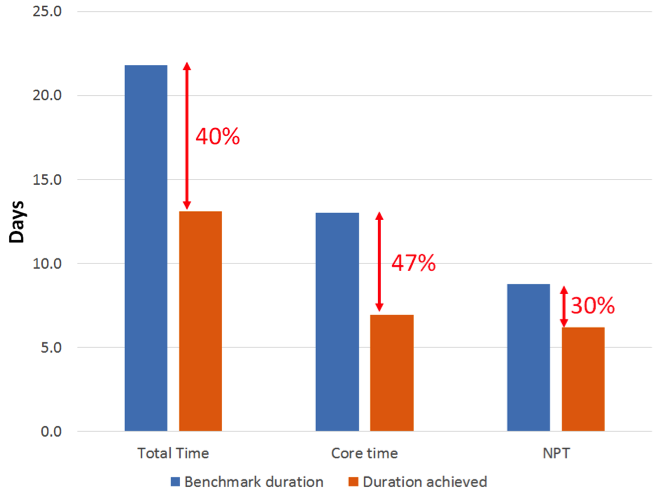

This project delivered outstanding results in a number of areas. The graph below shows how the time required for each overhaul was reduced compared to the original benchmark standard with an overall reduction of 40%. The core time (productivity whilst working) improved by 47% and Non Productive Time (when work was delayed) reduced by 30%. The team are now looking at how to roll out the principles of challenge planning and optimisation for other work.

1 – the RAM Capture in Progress

About the Author

Laurie Dummett

Laurie is the facilitator for our Maintenance Planning and Asset Management courses including, Maintenance Planning, Scheduling and Control, Cost Effective Maintenance, Certified Maintenance Planner, and Managing Shutdowns, Turnarounds and Outages

Laurie Dummett is an award winning consultant and trainer with over 25 years’ experience in maintenance. He has worked across five continents, in a wide variety of environments from the world’s largest oil refinery to a small bottling plant. Laurie has 10 years of maintenance management experience in the process industry, so brings a very practical approach to training. He moved into consulting with ABB Eutech as their global maintenance specialist where he led maintenance best practice panels, delivered a wide range of maintenance improvement projects and trained other consultants.

Laurie founded his own consultancy, in 2002 to focus on maintenance improvement and best of the best methodologies. As part of this, he developed a range of maintenance “models of excellence” with inputs from authors, international lecturers and some of the world’s leading consultants and operators.

Laurie remains close to the industry and continues to help operating companies, testing and refining his maintenance models in the process. His work in maintenance improvement has been recognized as best-in-class winning prestigious awards such as the UK Chemicals Industry Association national award for Excellence in Engineering.

Related Blogs

7 Steps to Reduce Maintenance Fixed Costs

Very few maintenance staff can describe a coherent and structured methodology for reducing maintenance fixed costs without undermining performance. It is unfortunate that there is no recognised methodology fo...

Tackling the Maintenance Fixed Cost Challenge Through Cost Effective Maintenance

In the past few months I have been privileged to have worked with maintenance professionals in Africa, Asia, Europe, America and the Middle East including people from a wide range of backgrounds from oil ...

What are you planning for? Surviving or thriving?

We have done a lot of maintenance reviews over the years and one of the key areas we check is how maintenance work is planned and managed. Most people recogn...

Turning the Credit and Collections Department into a Profit Earning Function

Below is a real-life case study by Jon Ray MICM. A few years ago, I was doing some consultancy work for one of the big European banks. This institution had some i...