The Wastes Management Hierarchy and The Circular Economy

For many in business, wastes that are produced are simply an overhead that must be accounted for and are a drain on profits; there is a fundamental acceptance that waste is inevitable! However with the right approach, the amount of waste produced and the related cost for disposal can be significantly reduced such that profitability can increase without increasing production output. This approach identifies ‘resources’ rather than ‘wastes’ and seeks to manage them in a resource-efficient way.

Resource efficiency describes the management of resources in a way that is consistent with the principle of sustainable development; it covers all aspects of resource management from efficient energy use to optimal manpower utilisation. In managing operations in a resource efficient way, compliance with regulatory controls is facilitated and can obviate the need for compliance by reducing resource use in a way that lowers levels below compliance limits. In supporting the principle of sustainable development it also encompasses the use of materials that minimise environmental impact, such as the use of paper and timber from sustainably management forests.

The concept is simple, yet in practice many companies fail to recognise the value of waste that they discard. These companies often tend to retain a focus on increased profits through increased turnover and fail to recognise that profitability can also be increased by maximising use of their existing resources – effectively decoupling economic growth from turnover considerations.

The wastes management hierarchy is the tool that is used to undertake wastes management activities in a way that meets the requirements of sustainable development through resource efficient measures. It requires that we manage wastes in such a way that the risk to the environment is reduced to an acceptable level while also striking a balance with economic and social considerations. When used effectively it will also ensure that waste management costs are minimised.

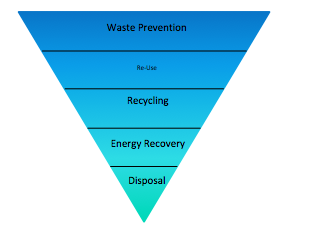

Globally there are a number of variations on the wastes management hierarchy but it is often shown as in Figure 1.

The principle of this hierarchy is that the nearer you manage wastes to the top of the hierarchy (that is wastes prevention) then the more sustainable is the management process.

Wastes Prevention

The term wastes prevention has many synonyms that are used globally and can include terms such as avoidance, minimisation, reduction and elimination to name but a few, but whatever the name used, the underlying concept is simple and recognises that IF we don’t produce wastes in the first instance then we cannot cause pollution of the environment nor harm to human health. What is more, there are very real potential savings benefits through which companies can increase profit and a quick search of the internet will highlight thousands of examples of savings made by companies …… both large and small, as a result of waste minimisation activities.

To be effective in waste prevention activities, it is important to understand that waste disposal costs are just the easily visible cost of waste and that when we account for things like wasted raw materials, energy costs, labour, re-working and a range of other factors its true cost can be up to 25 times the cost of disposal and, according to WRAP (wrap.org.uk) potentially up to 4.5% of a company’s annual turnover.

A large number of case-studies and good practice in resource-efficiency can be found at http://www.wrap.org.uk/content/resource-efficiency-publications

Re-Use

Wastes Re-use addresses the re-use of materials where there is no significant processing. As with wastes prevention, re-use also offers the potential for cost as well as environment savings. Common examples of re-use include the re-use of second-hand clothes and other second-hand goods as well as the re-use of paper within the office environment.

The key factor is that because re-use involves little, if any processing there are no significant impacts upon the environment. For example, when paper is re-used it is difficult to imagine ANY negative impacts, but the recycling of paper often requires the use of a wide range of chemicals (such as bleaching agents and detergents) while a range of wastes including waste printing inks can also be produced.

Recycling

Unlike re-use, recycling DOES involve processing of the original material and a good example will be the recycling of metals. For example, an aluminium drinks can be melted down and made into a new aluminium product which MAY or MAY NOT be a drinks can. In general terms, wastes recycling switches perception from seeing wastes AS ‘wastes’ to seeing them as a VALUABLE resource.

Now if we take aluminium as an example, then according to Novelis:

- Recycling aluminium requires 95% less energy, and produces 95% fewer greenhouse gas emissions (GHG), than manufacturing primary aluminium.;

- Recycling 1 tonne of aluminium avoids the emission of about 9 tonnes of CO2 emissions; and

- Recycling aluminium reduces the use of natural resources and chemicals (caustic soda, aluminium fluoride and lime) and eliminates the need for bauxite ore to be mined.

Given that much of the cost of production is associated with the energy demand then 95% savings in energy result in VERY significant cost savings, and as a result, segregated aluminium cans have a value of approximately $1000 per tonne though this will vary by country and market conditions.

Wastes Recovery

Within the wastes management hierarchy ‘Recovery’ is below ‘recycling’ in terms of sustainability and as used means the recovery of value from wastes, beyond the materials themselves! So while when recycling we produce metal product from metal wastes in ‘recovery’ we can think of the recovery of energy from the incineration of wastes, and the recovery of energy from, for example, biogas generated in the anaerobic digestion of food and other organic wastes. In the case of Anaerobic Digestion we also have the potential to recover fertiliser value from the resultant digestate (where the digestate is the non-degradable organic fraction that remains at the end of the process)

Recovery of Energy Through Wastes Incineration

So once we have recovered value from wastes through re-use and recycling we can then recover further value by extracting entrained energy through incineration processes … known as Energy from Wastes Incineration (EfW). EfW maximises the resource value of wastes that cannot be managed by options further up the hierarchy. This may happen, for example, when wastes are contaminated, or where, for one reason or another, they cannot be segregated with the required degree of control needed for re-use and recycling. This can happen when wastes simply get wet!

When these wastes are burned in incineration processes, the heat that is produced can be used to generate steam and in turn can be used for electricity generation, district heating, or both. WHEN used for power and heat generation such facilities are known as Combined Heat and Power (CHP) plants.

In terms of sustainability, the extraction of this entrained energy means that fewer fossil fuels have to be burned in power stations to supply heat and energy demand and there is therefore a potentially significant secondary benefit through reduced emissions to atmosphere (that may contribute, for example, to acid rain!) AND reduced use of non-renewable resources such as coal natural gas and oil.

Furthermore, once the ash has been cooled it can be processed to produce materials for construction, and any ferrous metals within the ash can be extracted using an electromagnet and recycled.

Ideally an EfW incinerator will be designed to treat only those wastes that remain after re-use and recycling operations and in this way, resources will be managed in the most sustainable way possible.

The incinerators themselves are tightly regulated and emissions to atmosphere continuously monitored and controlled and from a waste-producers perspective, incineration of their waste avoids disposal to landfill and helps support company ‘green’ policies and related environment-friendly credentials.

Thus while recovery through incineration is lower in the hierarchy than recycling it can still have an important role in the sustainable management of wastes.

Disposal of waste to landfill is at the very bottom of the waste management hierarchy and yet many less well-developed countries it is the predominant waste management option where capital costs can be much less than other management options, according to the level of engineering employed.Landfill

A landfill should be a controlled, engineered facility that is designed and managed to reduce the impact upon the environment and will typically include engineered containment including impermeable liners and drainage layers, with associated collection and management of landfill gas and leachate. Whereas a dump is entirely uncontrolled with no management of environmental impacts!

However, when wastes as (seemingly) innocuous as paper is landfilled, it can breakdown to produce landfill gas (mainly carbon dioxide and methane – both so-called greenhouse gas emissions) and leachate (often with a high Biological Oxygen Demand (BOD) as well as high levels of ammonia and other contaminants. As landfills are in direct association with the surrounding environment, escaping gas and leachate can cause pollution of the environment and harm to human health. They can also attract vermin that cause local nuisance. It will clearly be much better to use options further up the hierarchy!

In more affluent countries, regulation and control is ensuring that landfill is no longer the cheapest option for the management of wastes and indeed that for many wastes it is far better to view them as resources and move their management up the waste hierarchy for environmental protection and often for increased income! As a result the percentage of waste that these countries landfill is reducing on a year by year basis and in the UK for example biodegradable municipal waste has fallen from about 80 % to landfill in 2001 to 49 % in 2010, and has continued to fall since.

Summary

Managing wastes according to the wastes management hierarchy supports the sustainable management of resources in a way that protects the environment now, and in the future. It can also lead to cost savings and increased profit, as well as facilitating legal compliance and supporting favourable corporate image.

If you have yet to explore the benefits of sustainable resource and waste management, there is no better time to start.

Attend a 5-Day workshop with Ken Westlake in Dubai:

Waste Management: A Modern and Sustainable Approach

For more information, contact PLUS Specialty Training

Related Blogs

Back to Nature

I suppose everyone will agree with me, even though my theory is not supported with numbers, that lately, the hours spent in front of screens, whether smart devices, laptops, or TVs, has increased tremendously....

Corona: Fight or Fright

The COVID-19 pandemic brings numerous concerns for humanity. With a few exceptions, all businesses are suffering from this virus that has crippled almost everything. However, the question for which I couldn’t...

Waste Management in the UAE

A new high-tech waste to energy (WTE) facility in Sharjah is to come on-line by 2020. Managed by the Emirates Waste to Energy Company (a joint venture between Masdar and Bee’ah) it will be capable of processing app...

Turning the Credit and Collections Department into a Profit Earning Function

Below is a real-life case study by Jon Ray MICM. A few years ago, I was doing some consultancy work for one of the big European banks. This institution had some i...